Market Overview

Non Woven Fabric is

material manufactured from short and long fibers bonded together by chemical,

mechanical, heat or solvent materials. These fabrics are broadly defined as

sheets or web structures that are bonded together either mechanically,

chemically or thermally. These engineered fabrics can be disposable that is

meant for single use or durable also. Various functions which these fibers

performed or accord to the main fabric are absorbency, stretch, tensile

strength, durability, acoustic insulation, filtration, softness, bacteria

prevention etc. Their structure varies

from crisp, harsh, hard to tear, soft to touch to extremely weak depending upon

the particular application they are put to use.

This nonwoven fabric is highly used in many industries like Filtration Industry, Automotive Industry, Home Textiles, Packaging Industry and many more to count. Their respective share in different sectors can be clearly judge from the various purposes they are being put into use.

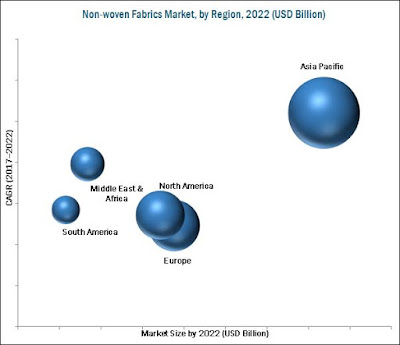

As per the report of the

Non Woven Fabric Market Research the market size for nonwovens globally is

estimated to grow from USD 22.62 Billion in 2016 to USD 34.85 Billion by 2022.

This market size is projected from 2017 to 2022. This project is based on the

analysis of Key Regions that is Asia-Pacific, Europe, North America, The Middle

East, Africa and Latin America. Among all Asia-Pacific is considered to be the

largest and fastest growing market during this period followed by North America

and Europe respectively. The reason for such high growth of this industry being

the rising awareness for hygiene and personal care. It has mandate the

manufacturers to use these fibers as they are highly bacteria resistant and

provide the required features to the main product making it highly suitable and

feasible for use.

On the basis of given

market report, it can be well assessed that nonwoven fabric market is expected

to witness a considerable growth in the coming years owing to the growth of

modern health care in developing countries and rising awareness of

environmental friendly fabrics. As at Jhanji Textiles also we manufacture these

fibers from PET flakes which are derived from 100% recycled PET bottles. These

Polyester based fabrics are also very cheap alternative to fabric and have high

tensile strength and durability.

Comments

Post a Comment